The Kaʻōhao Protocol

Distilled from many years of experience, we have developed specific procedures to address every aspect of the Resource Recovery operation, from food waste separation to worm bin bedding to composting to logging data to cleaning up. Many of the details for school Resource Recovery were perfected during our first few years at Kaʻōhao School, so we dubbed our standardized methodology the Kaʻōhao Protocol.

Although every school is different and we strive to blend in with their particular culture, the Kaʻōhao Protocol is consistent on every campus and provides stability, predictability, safety, efficiency, transparency, and productivity. The rigor of our science and data is unmatched.

For example:

Hot Composting via the Kaʻōhao Protocol

We use what are called static aerated piles, built upon a 12” pad of mulch. These piles take all post-consumer waste (plate scrapings and milk) as well as kitchen prep and surplus. The first layer is a base of one-to-two-inch diameter sticks, branches that serve to maintain good aeration and drainage deep within the pile. Pile temperature is taken before adding to the pile and noted in a log book/spreadsheet. Each bucket of food waste is weighed, the compiled weight noted in a log book/spreadsheet. Using a hose to saturate with water as the layers are constructed, mulch is alternated with layers of food waste with a ratio 3:1.

Typically one or two layers are added daily to a pile, and typically 4-5 piles are active simultaneously, rotating from pile to pile over the week. After adding to the pile, always finishing with a thick layer of mulch with no food exposed, five pukas called chimneys are poked with the handle of a pitchfork all the way down to the bottom stick layer, where the sticks can be slightly shifted to open up new channels for air and drainage.

The pile is covered with a 10’ x 10’ tarp with brightly-colored bricks at the four corners and arranged on top in an open circle arrangement to hold down the tarp. When the pile reaches 1,000 pounds of food waste, it is closed. The top brick arrangement is changed, the “code” to indicate the pile is no longer accepting food waste.

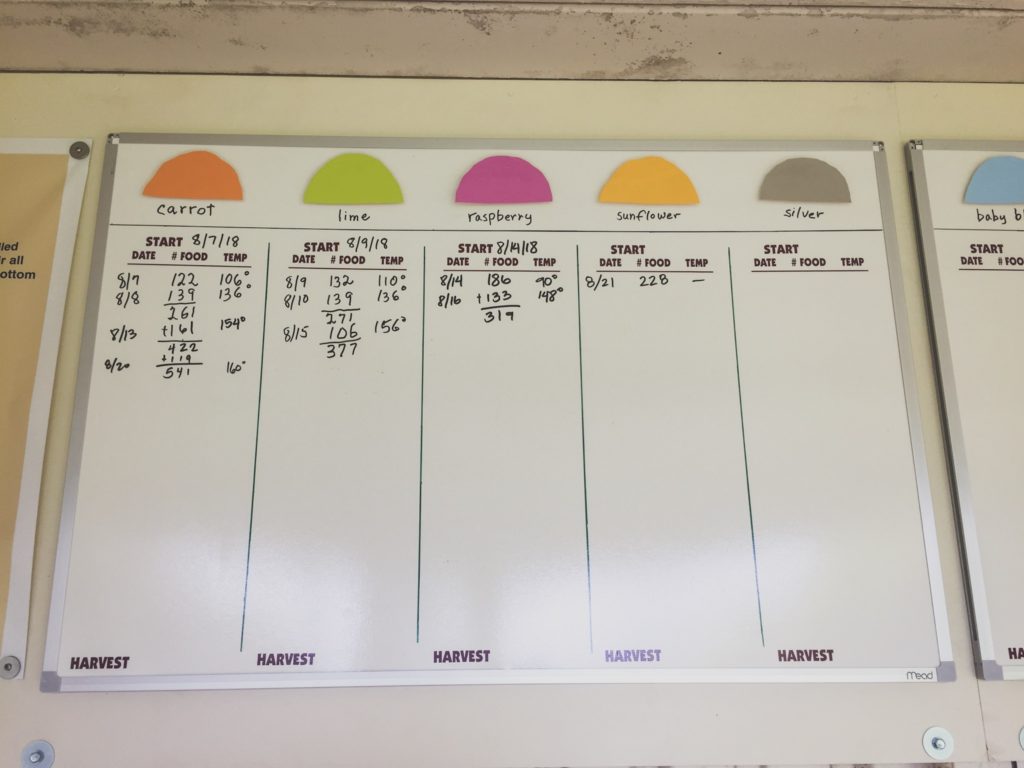

Publicly-posted

daily data boards show the history of each color-coded pile. The start

date is noted, then the date of every visit to the pile to include the pounds

of food waste and the temperature. These data illustrate the richness of

our finished compost –1,000 pounds of food – as well as the safety of our

product. Temperatures spike after a couple of days to between 140º and

160º and maintain that level the entire time the pile is being built and for

8-12 weeks afterward. This long thermophilic phase kills any pathogens

and phytotoxins, and far exceeds the food safety standard of 131º for four

days.

As the thermophilic phase winds down, each pile is visited with a “poke & soak” procedure every few weeks – vigorous perforation of the pile with a pitchfork to break up and aerate the material, re-wetting the pile and re-shaping so that breakdown proceeds uniformly throughout.

The mesophilic phase – when the familiar decomposer organisms take over from the thermophilic bacteria – varies considerably based on the invertebrate population at the site. From the last feeding of the pile, complete breakdown to compost typically takes six months to one year.

The finished compost is harvested using two custom-built screeners that each fit over four 10-gallon Sterilite totes. Screeners sit on overturned buckets and rub the material shoveled on their screen through to the buckets, then brush away any unprocessed bits. A team of ten – two shovelers and eight screeners – can harvest one pile easily in under one hour. Each 1,000-pound pile yields an average of 1-1/2 cubic yards of top-quality compost.

This is truly artisanal, hand-crafted compost that takes time, understanding, and practice to perfect, as does vermicomposting, green waste composting, and the many other activities included under the Kaʻōhao Protocol. Our goal is to build a workforce of experienced practitioners who can land on any campus and design, implement, and successfully manage a Zero Waste School program from Day One.

The apprenticeship period to become a Resource Recovery Specialist is 40 weeks.